Small and Medium Sawmill Innovation

Technology and scale killed the small-town sawmill. It’s a similar story across many industries.

We’re aiming to bring them back using innovation and new technology.

Current sawmilling equipment achieves high throughput by standardising each log, leading to low recovery of timber. Laser measuring/sorting and other similar technology is deployed with the goal of creating a standard sized piece of timber from each log. This is then broken down through automated machinery into final dimensional timber. This process results in a very low log recovery percentage, and it’s for this reason that a sawmill may specialise in one or limited products to achieve higher throughputs and slightly higher recovery. However, we must, as an industry, continue aiming higher for economic and ecological reasons and improve log recovery at every opportunity.

Flexible sawmills (such as where we started) designed for higher recovery and variable products are much lower throughput as a tradeoff. This often makes them commercially unviable as a solution to improving log recovery percentages. There currently is no automation or assistance available to this sawmill technology to allow for scale. These sawmills can only handle one log at a time.

We must, as an industry, continue aiming higher and improve log recovery at every opportunity

Hypothesis

Can we develop a high recovery and flexible sawmill achieve commercially meaningful scale in a production environment?

To do this we must solve 2 problems. Can a sawmill be developed that can do this task and can we develop software and technology to support the sawmill in achieving this?

We approached the sawmill development first, in a non-typical manner, by conducting several experiments attempting horizontal scale instead of faster processing of single logs (which is the industry norm and mostly requires standardized/perfect logs). We were successful in this novel approach and can mill through 5 logs at a time in a production environment. This has allowed us to create a commercially viable sawmill that’s high recovery capable of the next stage of development.

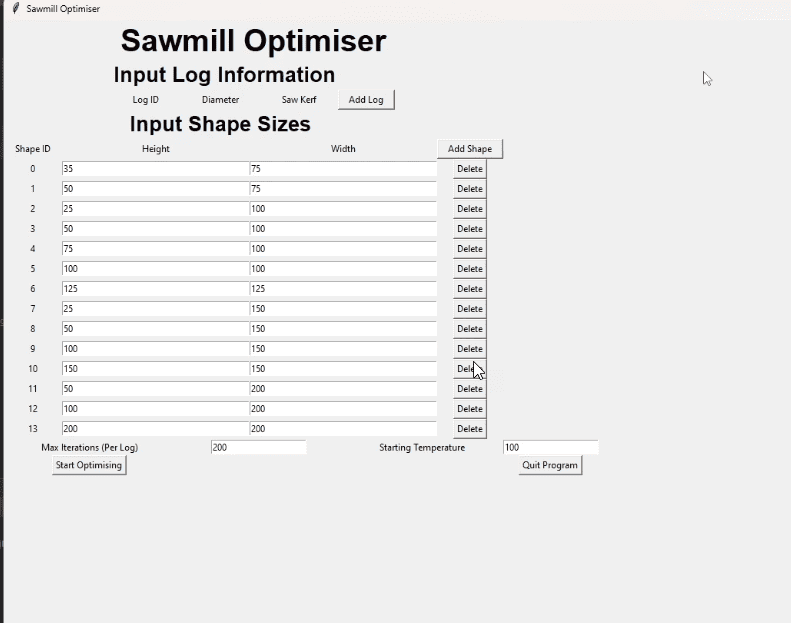

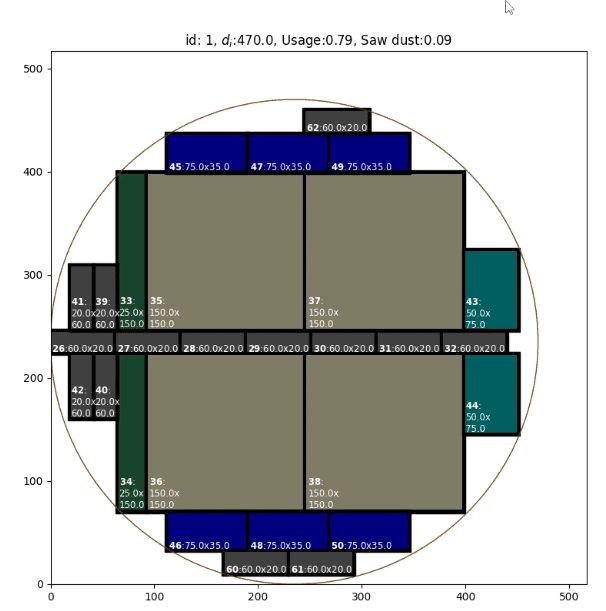

Log optimising algorithm development to support atomisation of milling.

It is not known if an optimisation algorithm can be developed based on random sized logs and random dimensions of timber to be cut from those logs. A further complexity/randomisation being errors (or defects) in logs present an additional layer of problems.

There are many software approaches to log optimisation, most of which are some variant of a database of predetermined sizes of logs and what you can cut out of them, theoretically. This approach doesn’t solve for

- variances in cutting lists (custom orders)

- variances in log diameters and quality

- discoveries of defects once cutting open the log (real-time updates and changes)

This problem is called the 2 dimensional irregular packing problem.

We have split the algorithm development to solve our unique version of the “2 dimensional irregular packing problem” into the following stages:

- Common timber sizes from perfectly circular logs

- Currently base code complete, now in testing stage

- Common timber sizes from perfectly circular logs but 1 defect in the face (such as allowing for the heart/pith to be removed in the log optimisation algorithm)

- Next stage of development

- Common and uncommon timber sizes from irregularly sized logs with 1 or more defects

- This stage allows us to go to live trials

- Further optimisation via real time analysis of logs through the creation of a dataset to train a machine learning library to perform log defect detections inside the log as we cut timber from it in order to recalculate the algorithm and make adjustments.

Machine learning detection of log defects development

Although it seems like AI is very fresh technology, Machine Learning via pattern detection in a semi-structured environment has been used in innovative and efficiency-gaining machinery across many years, ever-improving with the advancements of detection equipment.

The final stage of the project involves creating a training dataset in order to train a machine learning engine to visually detect defects in logs in a reliable manner and if so, mathematically account for them in the log optimising algorithm. We much be able to achieve the following:

- Ability to measure circumference and length of log

- Detect any defects on surface of log

- Knots, limbs, checks, swoop, rot, heart etc

- Detect any non expected defects throughout the log as its being milled

- Detect the limits of any defects throughout the log.

The outcome of a successful machine learning algorithm that can assess logs and determine the spatial dimensions of defects is the ability to reroute this information into the log optimising algorithm for better recovery of timber from logs.

What does this all mean for our sawmill and for regional development and the timber industry? The increase of viable small to medium sawmills in regional areas closer to the source of timber harvesting, decentralisation of processing, competitive environments and all the social, economic and environmental benefits that come with a thriving circular economy approach.